Permanent Magnets

Permanent magnets are so called because they are able to maintain a magnetic field in the

surrounding space as they are made from materials which have high retentivity/low permeability.

The field strength can vary considerably, depending on the flux density in the magnet and its

shape.

The simplest form of permanent magnet is a bar magnet, which is basically a piece of ferromagnetic material with a magnetic pole at each end. If the bar was formed into a closed loop, then the magnetic field would be fully contained within a closed circuit and no external field would exist. If a discontinuity were present in the loop, a flux leakage would still occur.

Neither bar magnets nor ring (looped) magnets have any use in MT. But, if a bar magnet is simply formed into a U shape, the magnetic lines of force will be concentrated in the gap between the magnetic poles; this provides an ideal configuration for Magnetic Particle Inspection.

Example of a permanent magnet material is ALNICO which consists of:

- 54% iron

- 18% nickel

- 12% cobalt

- 6% copper

- 10% aluminium

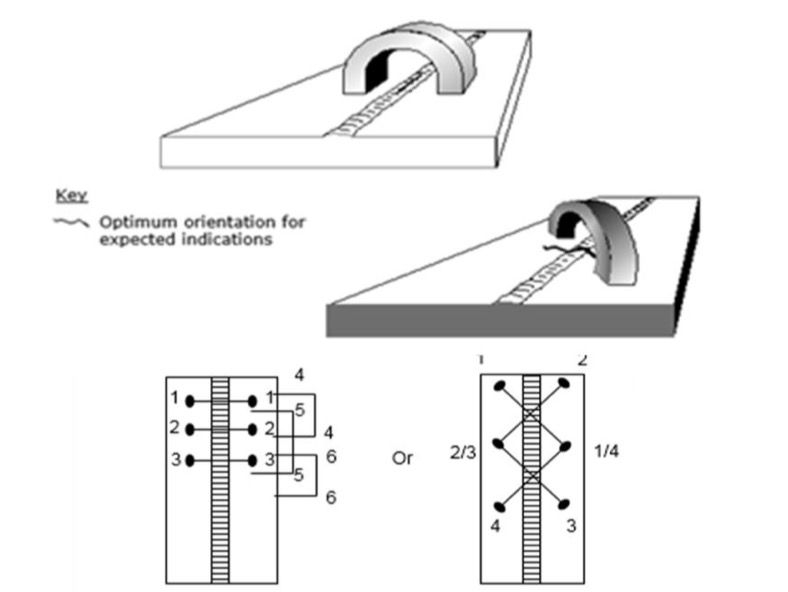

Permanent magnets provide magnetic flow only in the specimen and produce a longitudinal magnetic field between the poles.

The degree of magnetisation in permanent magnets is determined by the amount of pull required to lift the magnet clear of the workpiece, or by its lifting power.

The pull off force is the force that has to be applied to one pole to break its attraction to the surface, whilst leaving the other pole attracted.

The lifting power is the ability of the magnet to lift a piece of ferromagnetic material by attraction alone.

Certain specifications will state the minimum requirements for the strengths of permanent magnets. When not in use, a permanent magnet should have a keeper placed across the poles to short circuit the magnet and prevent loss of magnetism.

Some permanent magnets may have adjustable arms, others may have rollers attached to the poles; the rollers are set to keep the magnet just clear of the surface and enable it to be moved over the workpiece with relative ease.

BS EN ISO 9934-1 does not specifically cover permanent magnets. The old BS 6072 stated that

permanent magnets shall have a power capable of lifting 18 kg with a pole spacing 75 - 150 mm.

The pull off force shall have a value equivalent to at least 9 kg. The inspection area is usually

defined as a circular area between the poles.

Advantages of permanent magnets include:

- No power supply required (therefore can be used in remote areas)

- Inexpensive.

- No damage to the test piece from arcing.

- Relatively lightweight (easily portable).

- Easier to use on vertical or overhead work due to attaching to the test area, leaving both hands free.

Disadvantages include:

- Deterioration with wear/ abuse.

- Have to be pulled from the test surface.

- Magnetic particles attracted to poles.

- Limited application on awkward shapes.

- No control over field strength (unless adjustable arms are used).

- Only small areas examined in each position.

- Keeper required when not in use.

- Not recommended to be used in conjunction with flux indicators (flux indicators shall only be used to verify presence and direction of a magnetic field with this type of equipment, due to the unreliability of determining field strength).

- Toxic material when machined.

- Very hard/brittle material.

- Low flux density unless rare earth magnets used.

- Not as reliable as AC for detection surface discontinuities.